Testing

Innovative tests

Consistent high quality is an essential criterion for the success of a product. Baumann testsolutions ensure sustainable product quality. At every stage of production right up to final testing. Thanks to its extensive experience in the fields of electrical and mechanical testing, Baumann has been able to develop technologies in order to implement test procedures for PCBs or control units.

Test stations can be integrated

directly into assembly cells, incorporated into the production process via a test cell, or used once manufacturing has been

completed. Highly adaptable and customised test handler developments enable

cost-effective test station solutions to be supplied.

The construction of complete lines consisting of several test handlers is quite

simple. Optimum flexibility is ensured by the modular design of Baumann’s test

solutions.

Baumann test systems monitor the quality of your products worldwide. Everything from a single source – from a single adapter, through integration of the test software and handling, to a complete cell.

Application examples

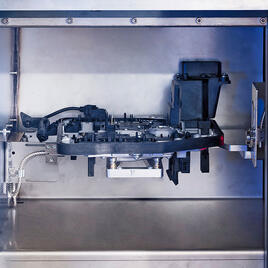

PCB test

Baumann offers a particular competitive advantage with regard to its solutions for testing PCBs. Single tester or combination of several testers - we already have the solution.

Control unit test

Different control units require individual test systems. In-house developments or the integration of test systems is one of our major strengths.

Temperature functional test

Testing in cold or hot conditions places very special demands on the equipment. Standard or individual solutions for testing PCBs or assemblies.

Testing PCB

At our in-house adapter production facility, we produce a variety of different, sometimes highly complex mechanical adapters and standardised adapters for testing PCBs.

Solutions for Image processing

From individual components and software to complete stations, we offer everything from a single source. In our very own vision laboratory, we develop individual solutions for our customers.

End of line (EOL)

The quality of the assembly processes is decided at the end of the production line. EOL test cells are specific cells individually adapted to final product testing.

Lean production – quality assurance from the outset

It has been the practice for many years in modern industrial manufacture to perform quality assurance throughout the entire production process. In order to incorporate quality controls perfectly into industrial automation solutions, Baumann engineers research and develop improved test systems for:

- mechanical test procedures

- sensor-based test procedures

- electrical test procedures

- thermal test procedures

Baumann Automation offers its customers perfect solutions for automated quality control procedures that check manufacturing-relevant parameters during on-going production and detect potential problems as early as possible.

A test station is integrated into the production process in a modular manner – either directly into assembly cells or via individual test cells.

Thanks to extensive experience in the field of automated quality control, Baumann offers a number of basic solutions that can be individually adapted to all customer requirements:

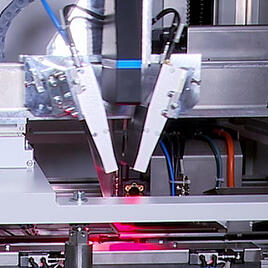

Optical inspection

Vision systems and state-of-the-art image processing have become an integral part of automation. Baumann is fully conversant with all these systems.

A team of specialists ensures that Baumann is always up-to-date in the optical inspection sector.

The company has extensive experience of image processing in the fields of:

- Position monitoring

- Component measuring, e.g. socket connectors

- Surface monitoring

- 3D measurements

Thanks to our extensive experience in the field of vision systems, we are able to optimise optical and digital control systems for 2D and 3D evaluation.

Precise defect detection, for the production of increasingly small electronic assemblies at high cycle rates with ever greater packing density, sets challenges that can only be met effectively with modular solutions - "Test solutions ... out of the box" - that can be integrated flexibly into every system.

Regardless of whether you are looking for standardised or customised solutions − Baumann is the partner of choice for vision Systems.

Baumann offers various system modules and solutions for both automated optical inspection (AOI) and objective optical end inspection (OOE).

With appropriate camera hardware we also provide the matching test software. All the relevant parameters, such as defect tolerances, can be fine tuned.

Baumann test solutions

Test solutions from Baumann can be perfectly integrated in all automation platforms and ensure efficient and precise quality management during production processes, as both stand-alone solutions and components for complex production lines. Needless to say, Baumann also offers comprehensive solutions for function tests (FT), in-circuit tests (ICT) and flashing.

Baumann always incorporates quality management systems in order to manage investments in the best way possible. Standardised and automated vision systems from Baumann detect defects precisely – e.g. press-fit defects, soldering defects, loading defects – and are cost effective due to their high cycle rates.

Discover everything you need to know about the basic range with the standard cells for perfect integration of all the Baumann Automation vision tests: