Assembly

Automation platforms for handling and assembly

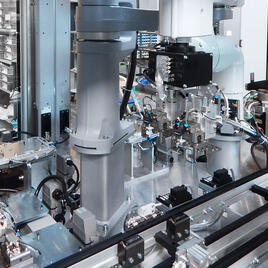

The advantage of the Baumann basic range with standardised solutions – in addition to being highly cost efficient – is the short delivery times for proven technology. Whether it is an integral part of an assembly line or a stand-alone cell. Each cell is equipped with control technology and standard connections and can be integrated quickly and flexibly into existing production lines.

As a special feature, the ro|box V10 enables extension of the control technology beyond one cell. For instance, additional handling and assembly cells can be connected without the need for extra control technology. Since, in this case, the costs for certain control elements are non-recurring, the Baumann system offers the best possible cost effectiveness.

All the systems are supplied with a multi-touch control panel and user-friendly software developments from Baumann. Furthermore, all customers profit from the comprehensive 24/7service with remote maintenance and fast spare parts delivery.

Assembly of special components

Special automation is particularly sought after for the assembly of odd-shaped special components when standard assembly machines fail to make the grade. In this case, Baumann provides solutions that have been specifically designed for special assembly purposes.

For example:

- Assembly inside housings

- Press-fit assembly of socket connectors

- Ultra-precision assembly within the micron range

- Assembly in an adhesive bed with force-time-displacement monitoring

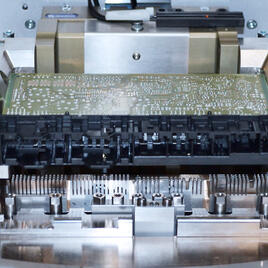

Baumann customers profit from the company’s extensive automation know-how – especially for the handling of complex components made from challenging materials, for instance:

- Printed circuit boards (PCB)

- Low temperature cofired ceramics (LTCC)

- High temperature cofired ceramics (HTCC)

- Direct bonded copper (DBC)

or: - Direct copper bonded (DCB)

- Die bonding, or chip bonding

- Lid clip

Control devices

One of our core competencies. Baumann assembly cells can be found in many different industries. Individually developed and implemented via different automation platforms.

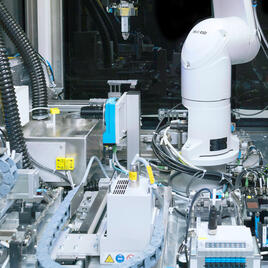

Sensors

The Baumann ro|box cell concept provides the basis for constructing a plant according to the principles of Industry 4.0 manufacturing.

Pumps

Robot cells are linked with a conveyor system to form one production line. The modular design enables a fully automated production process. Workpiece carriers with RFID system enable continuous traceability.

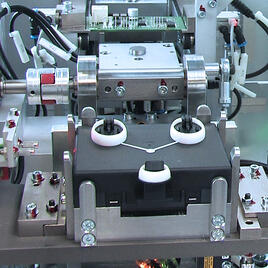

Press-fit

One of our standard process cells, available in a range of versions and expansion stages. Various component loading and unloading options augment the flexible application possibilities.

Fiber patch placement

The interaction of several robot systems enables the automated creation of complex components from individual fibre patches. The integrated cutting system (laser or ultrasonic) provides the patches.

Parking brake

Baumann offers fully interlinked assembly lines from the pre-assembly of sub-assemblies to the final assembly of the module with subsequent end-of-line testing and storage of the measurement data in an MES system.