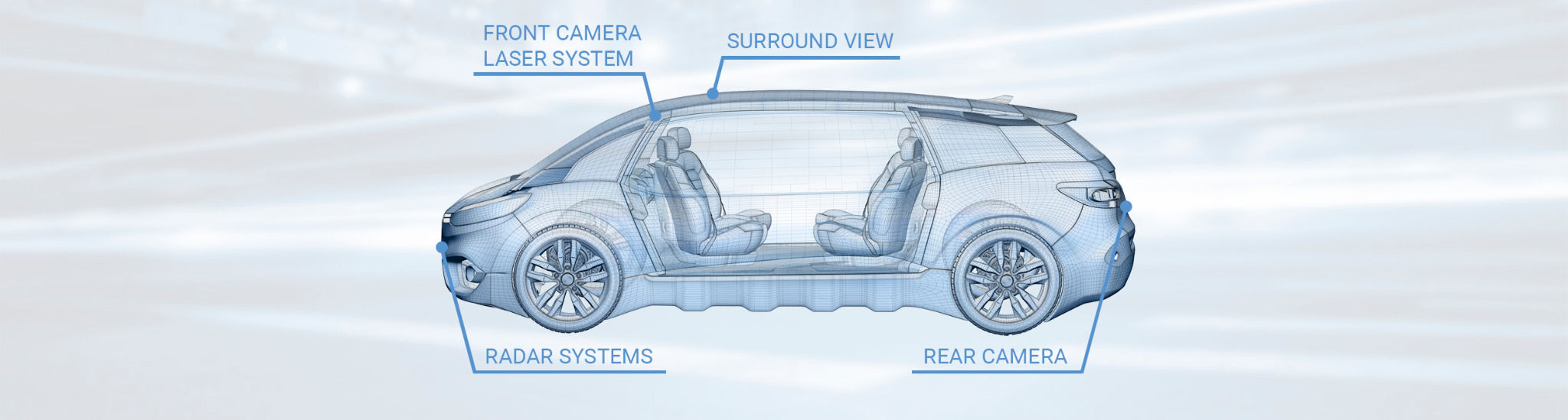

autonomous driving

To be able to drive autonomously, a combination of various sensor systems must be built into the vehicle to collect data from the surrounding environment. Cameras detect cars and people, road markings and traffic symbols. Laser scanners, radar and ultrasonic sensors measure the distance and speed of other objects in the surroundings. In addition, this combination also detects obstacles.

Automation for sophisticated driver assistance systems

Driver assistance systems are becoming increasingly sophisticated, both mechanically and electronically, and without automation, production processes would not be able to meet the high quality requirements. When it comes to plants for the production of driver assistance systems, Baumann Automation can draw on over 40 years of experience and know-how in automation and offer customers a solution optimally tailored to their requirements.

Testing and assembly working in perfekt harmony for greater reliability

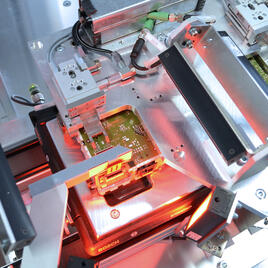

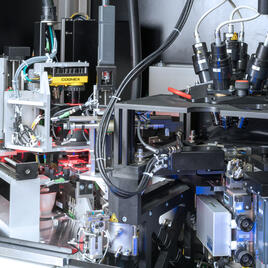

Traceability of all installed components and the finished assembly is essential for defect-free production. Testing the individual circuit board up to the finished unit is a decisive part of the production line. Standardised test procedures for circuit boards or other individual components are used. IC testers, flash systems, function and temperature testers (heat test up to +140 °C/ cold test at - 40 °C) are available at Baumann as standard cells. Component-specific test procedures are run during assembly. For this purpose, Baumann has developed special testers for the various driver assistance systems, such as image testers for camera systems or antenna testers for radar systems.

After assembly, the final tests are run on the assembly. For this purpose, various types of end-test processes are performed on the assemblies, as well as calibration, hardware and leakage tests. These special end-test procedures are also included in Baumann’s product range.

For classic processes such as depanellisation, adjustment, screwing, crimping, assembly, cleaning, laser marking and supplying intelligent components, Baumann solutions are based on flexible modular systems that can be specially adapted to customer requirements. Baumann also offers various process-optimised solutions for highly complex tasks, such as active alignment (adjusting the optics) or assembling flex cables.

Application examples

Assembly

Sensitive assembly tasks with high demands placed on precision and cleanliness require great experience in the field of sensor assembly. The assembly of dimensionally unstable components is not uncommon here.

Testing

Individually developed and standardised Baumann test systems already cover a wide range of the required testing tasks in the ADAS sector.

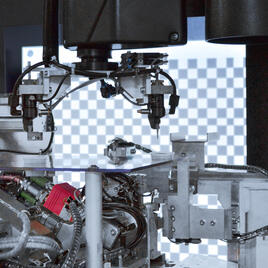

Camera

The assembly of camera modules with all manufacturing processes, especially the alignment of optical modules, was a special challenge for our development team.

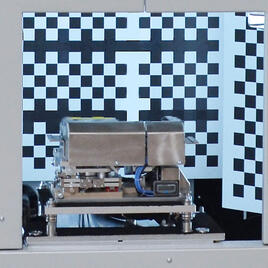

Radar

From the very beginning, Baumann accompanied the development of radar control units with its assembly and test cells. Calibration cells for the antenna, functional or leakage tests.

Laser

The development of products continues to gain momentum also in the field of LIDAR. Thanks to flexible and versatile basic systems, many test systems can continue to be used across product generations.

Active alignment

The active alignment of optics requires precision and know-how. The assembly skills of Baumann employees, combined with testing, software development and system integration, are reflected here.